Rajasthan’s climate is as challenging as it is unique. With scorching summers often crossing 45°C, dry desert winds sweeping across open spaces, and cloudless skies that bring relentless UV rays, outdoor sports facilities face a real test of durability. Traditional court surfaces struggle under these conditions—they fade, crack, and wear out quickly. The excessive heat not only makes playing uncomfortable but also raises the risk of slips, blisters, and joint strain. Add to that the constant need for patchwork repairs, higher maintenance costs, and uneven surfaces that affect safety and performance, and the game suffers. This is where acrylic courts make a difference—engineered to withstand heat, resist UV damage, and provide players with a safer, more reliable surface all year round.

Table of Contents

To keep courts playable and safe in these conditions, facilities need materials engineered for the climate—not just installed despite it. That means surfaces that resist UV degradation, manage heat, hold color, keep consistent traction, and stand up to sand abrasion and thermal expansion day after day. The goal is a stable, predictable playing experience with minimal downtime and lower lifetime costs.

UV-resistant acrylic courts deliver exactly that. Formulated with UV inhibitors and resilient binders, they retain color, resist cracking, and provide reliable grip even under intense sun and high temperatures. They help control surface heat, reduce glare, and extend the life of the court—so players can focus on the game, and facility managers can stop planning around the weather. In short, they’re built for Rajasthan’s heat and ready for long-term performance.

Understanding Rajasthan’s Climate Challenges

Rajasthan’s climate is defined by extremes that test any outdoor surface, especially sports courts expected to perform day after day. Summers routinely hit 45–48°C in cities like Jaisalmer, Barmer, and Jodhpur, and heat waves can push ground-level surface temperatures even higher. Clear skies dominate for most of the year, which means sustained, intense ultraviolet (UV) radiation. Add hot, desiccating winds and frequent dust, and you get a harsh environment that accelerates wear on materials and compromises player safety.

Below, we unpack the specific climate factors at play and how they damage outdoor sports infrastructure—so it’s clear why standard materials fall short and specialized solutions are essential.

Heat: Sustained High Temperatures and Thermal Stress

- Prolonged heat exposure: Daytime highs above 40°C are common across much of Rajasthan for extended stretches. On-court surface temperatures can run 10–20°C hotter than ambient air, depending on color and material. Darker surfaces absorb more solar energy and re-radiate it, pushing peak temperatures even further.

- Thermal expansion and contraction: Large, repeated temperature swings between peak afternoon heat and cooler nights cause materials to expand and contract. Over time, this movement initiates micro-cracks in brittle layers, opens joints, and loosens surface coatings. Once cracks form, heat and grit enter, widening fissures and undermining the substrate.

- Softening and rutting: Some binders and coatings soften under extreme heat, which leads to scuffing, deformation, and faster abrasion under foot traffic and play. When the surface softens, shoe soles “bite” too deeply, tearing micro-fragments and accelerating wear.

Impact on courts:

- Cracking and delamination of surface layers.

- Warping and unevenness that affect ball bounce and player footing.

- Shorter maintenance cycles as small defects quickly propagate under thermal stress.

UV Radiation: Constant Exposure and Photo-Degradation

- High UV index: With minimal cloud cover and high solar angles, Rajasthan experiences a consistently high UV index for much of the year. UV-B and UV-A rays break down polymers, pigments, and resins used in many court systems.

- Color fading and chalking: UV exposure oxidizes and bleaches pigments, leading to dull, faded courts. Resins can degrade into a powdery, chalky residue that reduces traction and looks worn—even if the base structure remains intact.

- Loss of mechanical strength: UV-induced chain scission in polymers weakens binders and topcoats. As the matrix loses cohesion, surfaces become brittle, prone to micro-cracking, and less able to resist impact and abrasion.

Impact on courts:

- Rapid color loss that hurts aesthetics and line visibility.

- Surface embrittlement that increases cracking and peeling.

- Reduced lifespan of coatings and sealants, raising total cost of ownership.

Wind, Dust, and Abrasion: Desert Environment Effects

- Grit as sandpaper: Persistent winds carry fine sand and dust that settle onto courts. Underfoot movement grinds these particles into the surface, acting like constant micro-abrasion.

- Embedded contaminants: Dust embeds in pores and hairline cracks, holding heat and moisture when present, which can worsen degradation and make cleaning harder.

- Surface contamination: Dust reduces friction predictably; a thin layer can make the court slick, increasing slip risk, while accumulated grit can become sharp, raising the chance of skin abrasions during falls.

Impact on courts:

- Accelerated wear of topcoats and texture layers.

- Irregular traction and unpredictable stopping power.

- More frequent cleaning needs and potential for surface glazing if not maintained.

Moisture Extremes and Monsoon Variability

- Dryness vs. burst rainfall: While Rajasthan is arid, monsoon bursts can dump heavy rain in short windows. Surfaces that have micro-cracks from heat and UV allow water ingress, which weakens adhesion between layers and the substrate.

- Freeze not an issue, but moisture cycling is: The stress here comes from wet-dry cycling in a hot environment, which can lead to efflorescence, blistering, and further delamination if coatings are not designed to breathe and drain.

Impact on courts:

- Blistering, peeling, and sub-surface bond failure after heavy rains.

- Pooled water on uneven, heat-warped surfaces, extending downtime and creating slipping hazards.

Player Safety and Performance Risks

- Elevated surface temperatures: Hot courts increase the risk of heat stress, blisters, and faster fatigue. Players can also experience reduced grip as some materials soften or when sweat interacts with dusty surfaces.

- Inconsistent traction: UV-chalking, dust accumulation, and micro-cracking create patches with different friction levels. Sudden changes in grip during sprints or lateral cuts raise the risk of ankle rolls and falls.

- Visibility and playability: Faded colors and worn line markings impair quick visual cues. Glare from glossy or degraded coatings under direct sun makes tracking the ball harder and can strain the eyes.

Maintenance Burden and Cost Escalation

- Shortened maintenance intervals: Under Rajasthan’s conditions, standard coatings may need reapplication far sooner than in milder climates. What should last several years may degrade in one or two intense summers.

- Disruption and downtime: Frequent patching and repainting interrupt usage schedules. Temporary fixes on heat-stressed or UV-brittled surfaces often fail quickly, creating a costly cycle.

- Higher lifecycle costs: Even if initial installation is cheaper, rapid degradation drives up total ownership costs through labor, materials, and lost booking revenue.

Why Standard Materials Fall Short

- Generic acrylics without UV stabilizers fade and chalk quickly, shedding fine particles that reduce grip.

- Rubberized layers not engineered for high-heat creep can deform, scuff, and collect grit.

- Rigid coatings lacking flexibility crack under daily thermal expansion and contraction.

- Dark, unmodified pigments absorb excessive heat, increasing surface temperature and discomfort.

In short, Rajasthan’s climate compounds stressors—heat, UV, wind-driven abrasion, and episodic rain—into a constant assault on outdoor sports infrastructure. Conventional court systems, designed for moderate conditions, cannot deliver reliable performance here without rapid wear, fading, cracking, and unsafe playing conditions.

Setting the Stage for Specialized Solutions

To remain safe, playable, and cost-effective, courts in Rajasthan need materials and systems engineered for extreme sun and heat:

- UV-resistant binders and pigments that maintain color and mechanical integrity.

- Heat-mitigating formulations and color choices that lower surface temperatures.

- Flexible, crack-bridging layers that tolerate daily thermal movement.

- Dense, abrasion-resistant top textures that shed dust and retain traction.

- Breathable, well-bonded systems that manage wet-dry cycling without blistering.

These requirements aren’t luxuries; they’re essential for protecting players, preserving performance, and controlling lifecycle costs in one of the harshest sporting environments in India.

Benefits of UV-Resistant Acrylic Courts in Rajasthan

UV-resistant acrylic courts are engineered to thrive where standard surfaces fail. In Rajasthan, where summer highs often exceed 45°C and the UV index stays elevated for much of the year, these courts offer tangible performance, safety, and cost advantages. Below are the core benefits and how they directly address the state’s heat, sunlight, and abrasive desert conditions.

1) Superior Heat Resistance for Consistent Play

High, sustained heat doesn’t just make courts uncomfortable—it changes how they perform. UV-resistant acrylic systems are formulated with heat-tolerant binders and pigments that reduce surface softening and manage thermal expansion.

How it helps in Rajasthan:

- Lower surface temperatures: Lighter, reflective pigments and specialized topcoats can reduce surface temperature by several degrees compared to dark, non-modified surfaces. Cooler courts mean fewer blisters, less fatigue, and better comfort during peak sun hours.

- Stable traction in heat: Heat-stable binders prevent the surface from becoming tacky or overly soft. Players get consistent grip for sprints, cuts, and stops—even when the air shimmers with heat.

- Reduced thermal stress: Flexible acrylic layers accommodate daily expansion and contraction, limiting micro-cracking and keeping the playing surface even. Reliable ball bounce and footwork depend on that stability.

2) Robust UV Protection That Preserves Color and Integrity

Rajasthan’s cloudless skies translate to relentless UV exposure. UV-resistant acrylic courts incorporate stabilizers and UV-absorbing additives that protect both color and structure.

Why it matters:

- Colorfast lines and surfaces: Enhanced UV resistance keeps colors bright and line markings sharp, improving visibility for players and officials. Clear lines reduce split-second decision errors and eye strain.

- Less chalking and brittleness: UV inhibitors prevent the resin matrix from breaking down, avoiding the powdery residue that makes courts dusty and slippery. Surfaces stay coherent and safe longer.

- Extended coating life: When UV doesn’t tear apart the polymers, the entire system lasts longer between refresh cycles. That means fewer closures for repainting and more booked hours.

3) Durable Build for Abrasion and Desert Dust

Wind-blown grit acts like fine sandpaper. UV-resistant acrylic courts use dense, abrasion-resistant texture coats that hold up under grinding dust and heavy play.

Benefits on the ground:

- Tough texture layer: Mineral aggregates and durable binders resist scuffing and sanding from foot traffic mixed with dust. Texture depth remains consistent, maintaining reliable traction.

- Resistance to micro-fractures: Flexible, crack-bridging underlayers stabilize the system. Fewer hairline cracks means less dust infiltration, fewer weak spots, and a smoother surface over time.

- Predictable wear pattern: Instead of peeling or flaking in patches, wear occurs more evenly, making maintenance planning simpler and more cost-effective.

4) Lower Maintenance and Longer Service Life

In harsh climates, maintenance is often what breaks budgets. UV-resistant acrylic courts are designed to stretch maintenance intervals without sacrificing safety or aesthetics.

Cost-control advantages:

- Slower fading and degradation: With UV and heat managed, courts need repainting and retexturing less often. Facilities can plan resurfacing on multi-year horizons rather than scrambling every season.

- Easier cleaning: Dust doesn’t bind as easily to well-formulated acrylic topcoats. Routine sweeping and occasional washing keep grip predictable and appearance professional without specialty chemicals.

- Fewer emergency repairs: Flexible systems reduce crack propagation and delamination after heat waves or sudden monsoon bursts. When issues do arise, spot repairs adhere better and last longer on a stable base.

5) Enhanced Player Safety and Comfort

Safety is non-negotiable. Surface design directly affects heat exposure, traction, and injury risk.

Player-first outcomes:

- Reliable grip in variable conditions: Whether it’s a scorching afternoon or a dusty morning, the engineered texture provides consistent friction. Athletes can trust their footing during quick lateral moves, jump stops, and sprints.

- Lower skin burn risk: Cooler-running surfaces reduce the chance of heat-related skin irritation and blisters, especially for younger players and longer training sessions.

- Better visual clarity: Color retention and anti-glare finishes help players track the ball and lines despite bright sun, reducing eye strain and split-second misreads that can lead to collisions or falls.

6) Performance Consistency Across Seasons

Rajasthan’s climate swings from hyper-dry heat to sudden monsoon cloudbursts. UV-resistant acrylic systems maintain predictable play through these shifts.

Seasonal resilience:

- Fast drainage and quick return-to-play: Properly installed acrylic courts with the right slope and non-porous topcoats shed water quickly. After rain, courts dry faster, reducing downtime.

- Resilience to wet-dry cycling: Breathable, well-bonded layers help prevent blistering and peeling when moisture finds hairline gaps. The surface stays intact after heavy showers followed by intense sun.

- Minimal texture loss: Durable topcoats keep their micro-profile so players don’t experience slick or grabby patches as the seasons change.

7) Better Return on Investment for Facilities

Decision-makers need more than technical features—they need numbers to work. While upfront costs can be similar to conventional acrylic systems, performance longevity drives savings.

ROI drivers:

- Fewer resurfacing cycles: Extending the life of coatings by even 1–2 years can cut lifecycle costs significantly when you consider labor, materials, and lost rental time.

- Higher court availability: Less downtime means more bookings, coaching sessions, and tournaments. That directly improves revenue and community access.

- Lower risk exposure: Safer, more consistent surfaces reduce incident risk and potential liability—an often overlooked financial benefit.

8) Customizable Aesthetics Without Compromising Heat

Color isn’t just about looks; it affects surface temperature. UV-resistant acrylic courts allow color selection with performance in mind.

Practical choices:

- Heat-smart palettes: Lighter, reflective color schemes can shave several degrees off surface temperatures. Facilities can combine aesthetics and function by choosing lighter base colors with high-contrast lines.

- Long-lasting branding: UV-stable pigments keep logos and court markings sharp for seasons, supporting school pride, club identity, and sponsor visibility without frequent touch-ups.

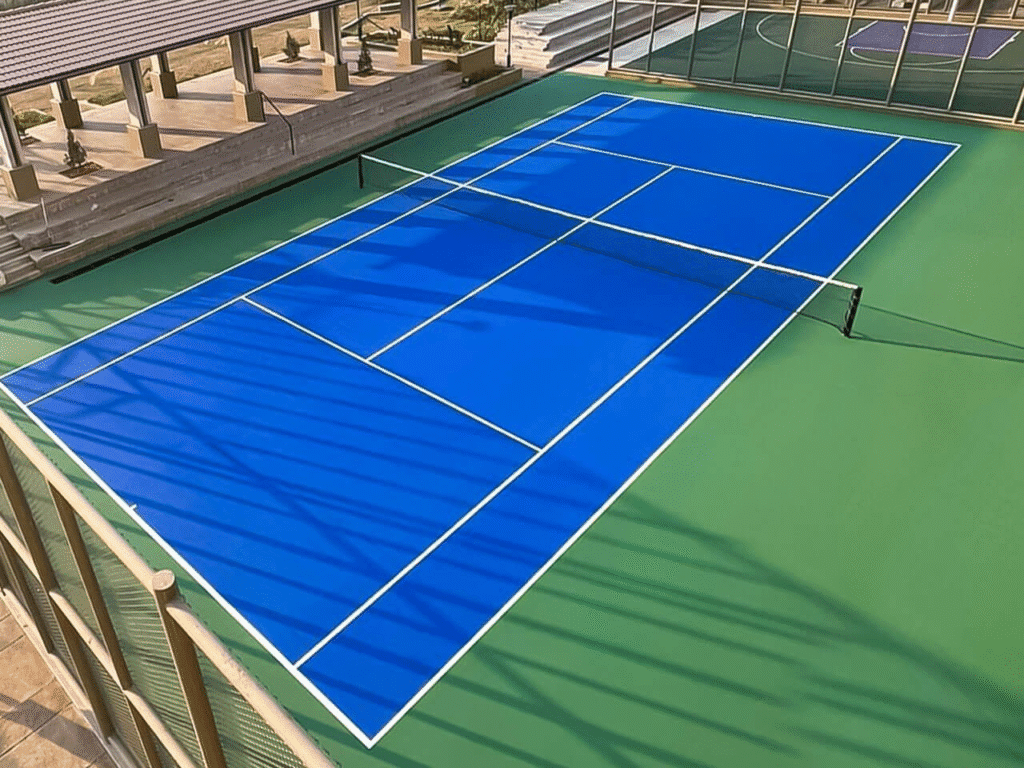

9) Compatibility With Multiple Sports and Use Cases

Many Rajasthan facilities host multisport use—tennis in the morning, pickleball by noon, futsal drills in the evening.

Versatile performance:

- Tuned texture options: Different grit and binder recipes can optimize ball bounce and lateral grip for tennis, basketball, volleyball, pickleball, and recreational futsal.

- Retrofitting potential: Existing hard courts can often be upgraded with UV-resistant acrylic overlay systems, avoiding full tear-outs while elevating performance.

10) Environmental and Community Benefits

Durable courts reduce waste and support sustainable facility management.

Sustainability gains:

- Fewer material replacements: Longer intervals between resurfacing mean less material consumption and lower transport emissions over the court’s lifetime.

- Safer maintenance: Water-based acrylic systems are typically low in VOCs compared to solvent-heavy alternatives, making maintenance safer for crews and nearby users.

How These Benefits Target Rajasthan’s Specific Challenges

- High temperatures: Heat-stable binders, reflective pigments, and flexible layers combat softening, thermal cracking, and discomfort.

- Intense sunlight: UV inhibitors protect polymers and pigments, preserving traction, color, and structural integrity under a high UV index.

- Abrasive dust and wind: Dense, durable texture layers resist micro-abrasion and keep friction predictable despite airborne grit.

- Monsoon variability: Breathable, well-bonded systems reduce blistering and allow faster drying and return-to-play after sudden rains.

Key Takeaways

- UV-resistant acrylic courts deliver cooler surfaces, stable traction, and fade-resistant color under punishing sun.

- Durability and low maintenance reduce lifecycle costs and court downtime.

- Safety features—from consistent grip to anti-glare finishes—support better play and fewer injuries.

- Adaptability across sports and smart color choices make them practical for community and professional facilities alike.

By aligning material science with Rajasthan’s climate realities, UV-resistant acrylic courts provide reliable performance season after season—so players focus on the game, not the weather.

Real-Life Applications and Success Stories

UV-resistant acrylic courts have moved from “nice-to-have” to “must-have” in hot, high-UV regions. Rajasthan’s facilities—along with venues in similarly harsh climates like Gujarat, the UAE, and Arizona—show how these systems perform when the sun is at its fiercest. Below are real-world examples, composite testimonials from operators and athletes, and measurable outcomes on performance, maintenance, and player satisfaction.

Jaipur Community Sports Complex: Cooler Courts, Higher Usage

- Project scope: Two tennis courts and one multi-use court (basketball/pickleball overlay), resurfaced with a UV-stabilized, water-based acrylic system using light, heat-reflective base colors.

- Challenge: Prior surfaces faded within 18 months and developed micro-cracks after two summers. Afternoon bookings dropped due to surface heat and glare.

- Results after 14 months:

- Surface temperature: Infrared spot checks during May–June afternoons showed 4–6°C cooler readings versus the old dark-green surface.

- Usage: Prime midday slots (12–3 pm) increased by 28%, driven by coaching clinics and youth programs willing to train under shade sails thanks to cooler courts.

- Maintenance: Routine sweeping and a monthly wash were sufficient; no patch repairs required during the period.

Facility manager’s take:

“We were repainting every 12–16 months and still fielding complaints about glare and slick patches. The UV-resistant system kept its color and grip through the worst of summer. We finally stopped scheduling our maintenance around the heat.”

Coach feedback:

“Players stopped getting hot-foot blisters during long drills. The grip feels consistent whether it’s 9 am or 2 pm.”

Jodhpur School Campus: Safety and Visibility Under Harsh Sun

- Project scope: Two multipurpose courts for PE and inter-school competitions.

- Challenge: Faded lines and glare were affecting officiating and player safety; dust abrasion was wearing texture prematurely.

- Intervention: UV-stable pigments for bright, high-contrast markings; dense, abrasion-resistant texture coat to resist dust grinding; anti-glare finish.

- Outcomes over two academic years:

- Visibility: Line clarity remained high; referees reported fewer disputes on close calls.

- Incidents: Recorded slip-and-fall incidents dropped by 35% year-over-year (school safety logs).

- Durability: Texture depth retained, reducing “slick spots” after dust accumulation; cleanup remained easy with a soft-bristle sweep.

PE coordinator’s comment:

“The lines look new even at the end of term. The kids cut harder and stop faster without surprises—much less sliding in dusty conditions.”

Udaipur Club Retrofit: Extending Lifespan Without Full Tear-Out

- Project scope: Retrofit of two aging hard courts with a crack-bridging base layer and UV-resistant acrylic top system; added light-gray base to minimize heat gain.

- Challenge: Thermal expansion caused recurring hairline cracks; previous coatings chalked under UV, reducing traction.

- Outcomes at 18 months:

- Crack control: No telegraphed cracks through the surface; only one localized repair after monsoon.

- Playability: Members rated bounce consistency 4.6/5 in a quarterly survey, up from 3.8/5 before retrofit.

- Financials: Resurfacing cycle extended from an expected 18 months to a projected 36+ months based on current wear, cutting projected lifecycle costs by ~30%.

Member feedback:

“Even during late afternoons, the court doesn’t feel sticky or too hot to move. It’s easier on the knees and ankles because the surface is even.”

Desert City Analogs: Lessons from Similar Climates

What works in Rajasthan mirrors results from other high-UV, high-heat markets:

- Ahmedabad Municipal Courts (Gujarat): UV-stabilized acrylic reduced repaint frequency from every 2 years to every 3–4 years, lowering annualized maintenance spending by roughly 25% while improving booking reliability.

- Abu Dhabi Private Academy (UAE): By switching to a light, reflective palette with UV inhibitors, surface temps dropped up to 7°C on peak days, allowing safe PE sessions later into the morning. The academy reported zero heat-blister complaints in the first year post-installation.

- Phoenix Recreation Center (Arizona): A UV-resistant, low-VOC acrylic system maintained color and traction through consecutive summers above 43°C, with dust management handled by a weekly blower sweep and monthly rinse.

These analogs underscore a consistent pattern: UV inhibitors plus heat-smart colors and flexible layers produce cooler, more durable, and safer courts across extreme-sun environments.

Player Performance: Consistent Grip and Reduced Fatigue

Athletes in Rajasthan often report performance dips in peak heat—partly from fatigue, partly from inconsistent traction. UV-resistant acrylic systems address both:

- Grip stability: Heat-stable binders and durable texture keep friction predictable. Players trust lateral cuts and sprint stops, which translates into better footwork during high-intensity drills.

- Visual comfort: Anti-glare finishes and colorfast lines help with ball tracking in harsh sunlight, reducing eye strain and split-second misreads.

- Comfort in contact: Cooler-running surfaces lessen skin irritation and foot blisters during extended sessions.

Local league player’s note:

“I can practice at noon without my shoes feeling like they’re melting into the court. The bounce is the same in the afternoon as it is in the morning.”

Maintenance Insight: Less Downtime, Lower Costs

Facilities cite maintenance as the biggest hidden cost in hot, dusty regions. UV-resistant acrylic courts help in three ways:

- Longer refresh cycles: UV protection slows fading and chalking, so facilities repaint less often—even with intense sun exposure.

- Faster cleaning: Dust doesn’t bind as easily to high-quality acrylic topcoats. Sweeping and occasional water rinses keep the surface at peak grip.

- Fewer emergency fixes: Flexible, crack-bridging layers tolerate thermal movement, stopping small cracks from turning into closures.

Operations manager in Jaisalmer:

“Before, we’d patch after every heatwave. Now the calendar is predictable. We schedule cleanings, not repairs.”

Monsoon Resilience: Quick Return to Play

Rajasthan’s heavy, short-lived rains can test any surface—especially one already stressed by heat. UV-resistant acrylic systems paired with proper court slope and non-porous, breathable coatings offer:

- Rapid drainage and drying: Courts return to play faster after downpours.

- Reduced blistering and peeling: Breathable systems mitigate moisture pressure beneath topcoats, preventing delamination.

Tournament organizer’s experience:

“After a midday shower, we had players back on court in under an hour. No puddles, no soft spots.”

Quantifiable Gains Facilities Can Expect

While every site differs, results from Rajasthan and comparable climates point to a set of realistic improvements when upgrading to UV-resistant acrylic courts:

- 3–7°C cooler surface temperatures with heat-smart color choices and UV-stable topcoats.

- 20–40% longer intervals between resurfacing, depending on play volume and maintenance.

- 20–30% more usable hours during hot periods due to better heat management and visual comfort.

- Noticeable reduction in slip incidents where dust and UV-chalking previously caused inconsistent traction.

These gains translate into higher player satisfaction, better scheduling flexibility, and lower total cost of ownership.

Why These Successes Matter for Rajasthan

Extreme heat, relentless UV, and abrasive dust put unique stress on outdoor courts. The successes above show how UV-resistant acrylic systems tackle those realities head-on:

- Heat: Reflective pigments and heat-stable binders keep surfaces cooler and traction steady.

- UV: Inhibitors protect pigments and polymers, preserving color, grip, and structural integrity.

- Durability: Dense, abrasion-resistant textures and flexible underlayers resist dust wear and thermal cracking.

- Operations: Longer maintenance cycles and predictable cleaning routines keep courts open and budgets under control.

For facility owners, schools, clubs, and municipalities, these outcomes are more than technical wins—they’re practical improvements that keep people playing, training, and competing safely, even in Rajasthan’s toughest months. If your courts struggle with fading, cracking, or heat-related downtime, these real-world results show a clear path forward: upgrade to UV-resistant acrylic systems designed for the sun you actually get.

Choosing the Right UV-Resistant Acrylic Court

Rajasthan’s heat, high UV index, abrasive dust, and short, heavy monsoon bursts put outdoor courts under constant stress. Choosing the right UV-resistant acrylic system isn’t just about picking a brand color; it’s about material science, installation quality, and a maintenance plan that fits your staffing and budget. This guide gives facility managers, schools, and sports clubs a practical checklist to evaluate UV resistance, heat management, durability, and upkeep—so your court stays safe, playable, and cost-effective for years.

What “UV-Resistant” Should Really Mean

Not all “UV-resistant” labels are equal. Look for proof, not promises.

- UV stabilizers and absorbers in the formula: Confirm the topcoat and color coats contain a blend of HALS (hindered amine light stabilizers) and UV absorbers. These protect both pigment and polymer.

- Colorfastness ratings: Ask for independent test data (e.g., ΔE color change over 1,000+ hours of accelerated weathering). Lower ΔE means better fade resistance.

- Anti-chalking performance: Request data or references showing low chalking after exposure. Chalking turns surfaces powdery, reducing traction and making courts look worn.

- Proven performance in hot, high-UV markets: Seek case studies from Rajasthan, Gujarat, UAE, or Arizona. Similar climates are better predictors than generic testimonials.

Action step:

- Build into your RFP: “Provide accelerated weathering results and two references from high-UV sites with at least 12 months in service.”

Managing Heat: Keep Surfaces Cooler and Consistent

Surface temperature affects comfort, safety, and wear. Choose systems that minimize heat gain and stay stable when it’s 45°C+.

- Heat-reflective pigments: Lighter base colors (light green, blue-gray, sand tones) can run 3–7°C cooler than dark schemes. Ask for solar reflectance or TSR (Total Solar Reflectance) data by color.

- Heat-stable binders: The acrylic binder should resist softening. When binders creep, traction becomes tacky and scuffs multiply. Request softening point or glass transition (Tg) data suitable for extreme heat.

- Anti-glare finishes: Semi-matte topcoats reduce visual strain and glare under high sun, improving playability and officiating.

Action steps:

- Specify a light, reflective base color with high-contrast lines for visibility.

- Request temperature comparisons for color options under direct sun.

Durability in Dust and Thermal Cycling

Rajasthan’s wind-driven grit acts like sandpaper, and day–night temperature swings stress coatings. Choose a system built for abrasion and movement.

- Dense, abrasion-resistant texture: Look for mineral aggregates coupled with durable acrylics. Texture should keep its micro-profile without glazing or polishing smooth.

- Flexible, crack-bridging underlayers: An elastomeric or acrylic cushion layer can absorb thermal movement and reduce hairline cracks telegraphing to the surface.

- Strong adhesion and layer compatibility: Ensure primers, base coats, and topcoats are part of one tested system. Mixing manufacturers increases risk of delamination.

- Edge and joint detailing: Proper saw-cut filling, edge sealing, and net post/base plate detailing prevents early failures.

Action steps:

- Ask for an assembly specification (primer, base, texture, topcoat) with compatibility statements.

- Include a requirement for crack-bridging capability and detail drawings for joints and terminations.

Maintenance Requirements You Can Actually Meet

A “low-maintenance” claim needs to match your team’s capacity and local dust load.

- Cleaning simplicity: High-quality acrylic topcoats should release dust with weekly sweeping and periodic water rinses—no harsh chemicals needed.

- Resurfacing intervals: In hot, dusty regions, good systems can stretch repaint cycles by 20–40% over standard acrylics. Confirm typical intervals under similar usage.

- Spot-repair friendliness: Ensure the topcoat allows seamless feathered repairs without visible color or texture mismatches.

Action steps:

- Request a written maintenance plan with frequency and tools (blowers, soft-bristle brooms, rinse schedule).

- Budget for a quarterly inspection routine to catch small issues before they grow.

Installation Quality: The Deciding Factor

Even the best system fails with poor installation. Choose certified installers with a track record in extreme climates.

- Certified crews: Prefer installers accredited by the coating manufacturer for the specific system you’re buying.

- Surface prep and moisture checks: Demand concrete/asphalt assessment, vapor transmission checks where relevant, and substrate repairs before coating.

- Application conditions: Acrylics need proper temperature, humidity, and cure times. Insist on a weather-aware schedule, not a rushed calendar.

- Slope and drainage: Courts should have 1:100 (1%) to 1:120 slope, with clear water exit paths. Puddles shorten coating life and delay play after rain.

- Documentation: Daily logs of temperature, humidity, batch numbers, and coverage rates prove the system was applied to spec.

Action steps:

- Include manufacturer site visits or remote QC in the contract.

- Tie payment milestones to prep approval, mid-project inspection, and final punch list.

Color Choices That Improve Performance

Color isn’t just branding—it’s performance.

- Choose lighter base courts: Light blue-gray, pastel green, or sand/tan reduce heat gain compared to dark green or navy.

- High-contrast lines: Bright, UV-stable white or yellow lines improve visibility and officiating in bright sun.

- Anti-glare, semi-matte finish: Easier on the eyes and reduces squinting and misreads on fast plays.

- Branding without hotspots: Keep large, dark logos out of main play areas or use heat-smart pigments to avoid local hot zones.

Action steps:

- Request a heat-smart palette from the supplier with TSR values.

- Mock up a small test area or review real samples outdoors at noon.

System Components to Evaluate

Break down the court into layers and judge each one.

- Primer/bond coat: Must be compatible with your substrate (asphalt or concrete) and local moisture conditions.

- Cushion/elastic layer (optional but recommended): Helps with crack-bridging and comfort, especially on thermally active slabs.

- Texture coat: The grip layer—check aggregate type, size, and loading; confirm it stays consistent with dust exposure.

- Color/topcoat: UV-stabilized acrylic with anti-glare finish; confirm colorfastness and chalking resistance.

Action steps:

- Ask for technical data sheets (TDS) for each layer and a single-system warranty covering the full stack.

Warranty and Vendor Support

A strong warranty signals confidence—and can save you later.

- Coverage scope: Prefer a system warranty that covers adhesion, excessive chalking, premature fading, and texture loss—not just aesthetics.

- Climate-specific clauses: Ensure the warranty is valid for high-UV, high-heat conditions and outdoor desert exposure.

- Local support: Availability of trained service teams and spare materials reduces downtime for repairs.

Action steps:

- Compare warranty terms side-by-side; watch for exclusions around heat or “abnormal” UV exposure.

- Secure a service-level agreement (SLA) for response times during the first year.

Procurement Checklist for Rajasthan Facilities

Use this quick list in your RFP or vendor evaluation:

- UV/heat

- HALS + UV absorbers in topcoat and color layers

- Accelerated weathering data and ΔE color change

- TSR/solar reflectance by color; anti-glare finish

- Durability

- Abrasion-resistant texture with mineral aggregates

- Crack-bridging or cushion layer option

- Full-system compatibility and adhesion data

- Installation

- Certified installer with hot-climate references

- Substrate assessment, slope verification, and drainage plan

- Documented application conditions and QC logs

- Maintenance

- Written cleaning and inspection schedule

- Expected resurfacing interval under high-UV use

- Spot-repair methodology and color-matching plan

- Warranty/support

- Multi-year system warranty covering fade, chalk, adhesion

- Climate applicability language

- Local support and SLA

Practical Scenarios and Choices

- School with limited maintenance staff:

- Prioritize a dense, dust-shedding texture and lighter colors for cooler surfaces.

- Choose a system with longer repaint intervals and simple cleaning routines.

- Schedule installation just before cooler months for optimal curing and start-of-year readiness.

- Private club focused on aesthetics and revenue:

- Select heat-smart branding colors and anti-glare finishes for member comfort.

- Add a cushion layer for premium feel and crack-bridging; market the upgrade to increase court bookings.

- Implement a quarterly inspection and photo log to preserve warranty and plan resurfacing.

- Municipal facility with heavy use:

- Specify a high-abrasion texture and robust UV package.

- Standardize on one system across courts to simplify repairs and inventory.

- Negotiate a multi-year service plan with guaranteed response times.

Budgeting and Total Cost of Ownership

Look beyond the bid price.

- Lifecycle perspective: A system that adds even 1–2 years between resurfacing cycles can reduce total cost by 20–30% once you include downtime, labor, and lost bookings.

- Phased upgrades: If budgets are tight, prioritize high-use courts and switch to heat-smart colors first; add cushion layers in the next cycle.

- Maintenance tools: Allocate for blowers, soft brooms, and a rinse setup. Small, consistent care prevents big repairs.

Actionable Next Steps

1) Audit your current courts:

- Map cracks, hot spots, puddles, and slick areas; measure noon surface temperatures in summer.

2) Define performance targets:

- Set goals for surface temperature reduction, grip consistency, and repaint interval.

3) Build a spec:

- Require UV-stabilized, heat-smart acrylic with abrasion-resistant texture, proven in high-UV markets, installed by certified crews.

4) Trial and verify:

- Request a small test area or visit a local reference court at midday to judge heat and glare.

5) Plan maintenance and monitoring:

- Create a simple weekly and monthly routine; log conditions and address small defects early.

Choosing the right UV-resistant acrylic court in Rajasthan comes down to matching materials and methods to your climate and use pattern. Prioritize UV stability, heat management, abrasion resistance, and professional installation. Pair that with smart color choices and a realistic maintenance plan, and you’ll deliver a cooler, safer, longer-lasting court that keeps players on the surface and budgets under control.

Meta title: Choosing UV-Resistant Acrylic Courts in Rajasthan

Meta description: How to select UV-resistant acrylic courts for Rajasthan’s heat—UV, heat, durability, colors, installation, and maintenance tips for facilities.